Download the

Download the ROI Sheet

Our engineering team has leveraged our expertise in supercritical carbon dioxide to design and deploy platforms for use in supercritical water oxidation and processing.

All supercritical water applications require high temperature (over 400°C) and moderately high pressure to achieve the critical point of water. Corrosion resulting from the highly reactive properties of supercritical water make these some of the most challenging applications of supercritical technology.

To meet these challenges, superior engineering and design expertise are required. This is exactly what Supercritical Fluid Technologies delivers. Key components include:

- Special materials, such as Inconel and Hastelloy, used for vessel linings and tubing to tolerate the highly corrosive environment.

- Water and process streams pumps able to deliver liquids at high pressure, maintaining precise flow and pressure control.

- Heat exchangers able to handle high heat transfer rates at high temperatures while maintaining precise temperature control.

- Reaction vessels that maintain exact temperature and pressure under flow.

- Reliable leak-free seals that withstand harsh operating environments.

- Efficient downstream processing, including cooling of heat exchangers and collection vessels, gas/liquid separation and pressure control.

- Custom system process controls, including manual valves with local process parameter display and control, and complete remote operation with computer process control and data acquisition.

Supercritical Water Oxidation (SCWO)

The goal of SCWO applications is to either purify a material by breaking down any contaminants into harmless compounds or to take a known hazardous material and break it down into simple, safe materials. In both instances the goal is to ensure that no hazardous compounds remain in the final product or escape into the environment.

Case Studies #1 – Drinking Water Purification

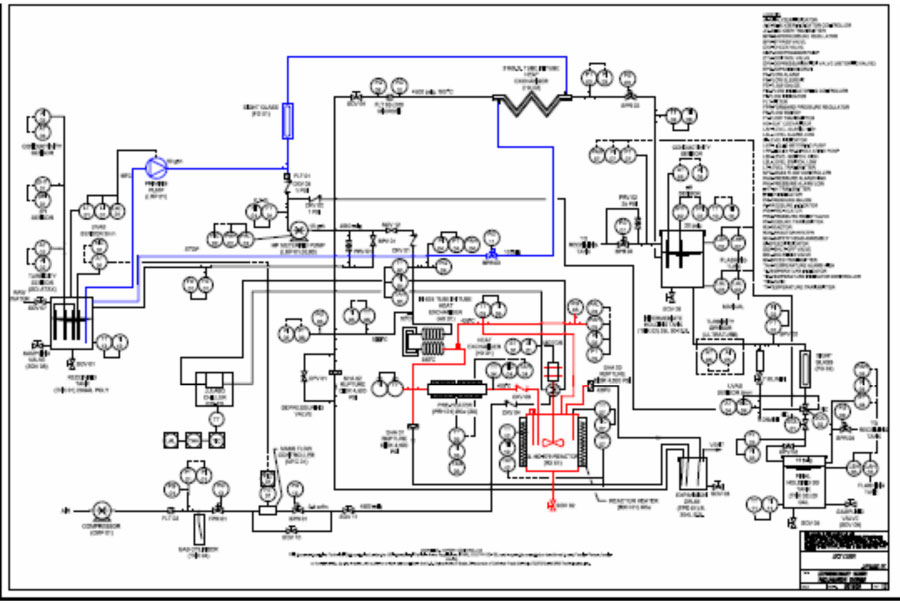

The US Department of Defense expressed interest in using supercritical water oxidative processes for the purification of drinking water for soldiers in the field. In conjunction with the DRS SSI C3-Group, SFT specified, designed, and deployed 2 Pilot Scale SCWO units that remove contaminants and produce 15 gallons per hour of purified water. Based on the success of this proof of concept work, we are developing units capable of purifying 150 gallons per hour.

The US Department of Defense expressed interest in using supercritical water oxidative processes for the purification of drinking water for soldiers in the field. In conjunction with the DRS SSI C3-Group, SFT specified, designed, and deployed 2 Pilot Scale SCWO units that remove contaminants and produce 15 gallons per hour of purified water. Based on the success of this proof of concept work, we are developing units capable of purifying 150 gallons per hour.

Not only do these units process water in an extremely corrosive environment, but our engineers employed an array of quality sensors to detail the quality of the water flowing into the system and the quality of the water flowing out of the system as part of the complete solution.

Not only do these units process water in an extremely corrosive environment, but our engineers employed an array of quality sensors to detail the quality of the water flowing into the system and the quality of the water flowing out of the system as part of the complete solution.

Case Studies #2 – Waste Stream Destruction

A client came to us with an interest in developing a safe and environmentally sound process for the destruction of an isopropyl alcohol waste stream which contained trace amounts of a controlled substance. Supercritical Fluid Technologies worked with the client to create a process flow and build a manually operated supercritical water oxidation system to eliminate these contaminants from the waste stream. Long term plans are to construct a full scale plant once proof of concept is complete.

A client came to us with an interest in developing a safe and environmentally sound process for the destruction of an isopropyl alcohol waste stream which contained trace amounts of a controlled substance. Supercritical Fluid Technologies worked with the client to create a process flow and build a manually operated supercritical water oxidation system to eliminate these contaminants from the waste stream. Long term plans are to construct a full scale plant once proof of concept is complete.

Supercritical Water Processing

Unlike SCWO, the goal with supercritical water processing is to selectively break down a material, yielding the desired product(s). To accomplish this, process conditions are carefully controlled so that the decomposition of the starting material is limited and directed. Precise temperature, pressure and resonance time within reactor are essential to obtain the desired product mixtures.

Case Studies #1 – Biofuel Production

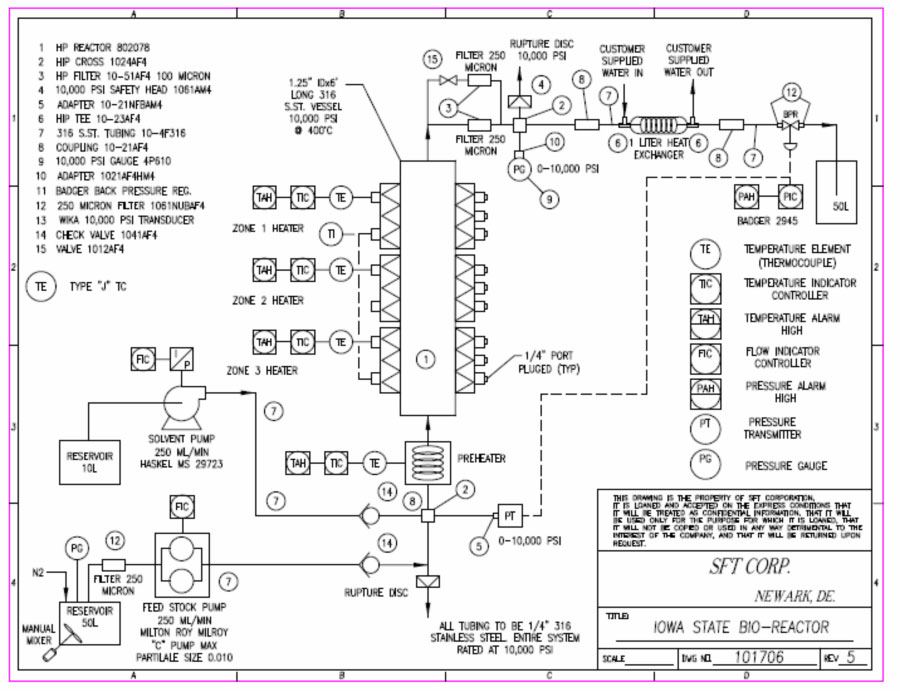

In conjunction with a US Department of Energy grant to the Iowa State University, Supercritical Fluid Technologies developed and built a custom Supercritical Bio Reactor designed to produce biofuels.

In conjunction with a US Department of Energy grant to the Iowa State University, Supercritical Fluid Technologies developed and built a custom Supercritical Bio Reactor designed to produce biofuels.

This incredibly precise, high-tech application involved a using a supercritical water stream to process a biomass/methanol slurry. The result was the successful synthesis of Biodiesel under catalyst-free supercritical methanol reactions.

Multiple experiments were performed in a high pressure batch reactor using a variety of oils at different temperatures, and a range of methanol to oil ratios. The experiments achieved excellent results, identifying ideal temperatures and ratios for production processes.

Multiple experiments were performed in a high pressure batch reactor using a variety of oils at different temperatures, and a range of methanol to oil ratios. The experiments achieved excellent results, identifying ideal temperatures and ratios for production processes.

Case Studies #2 – Petrochemical Applications

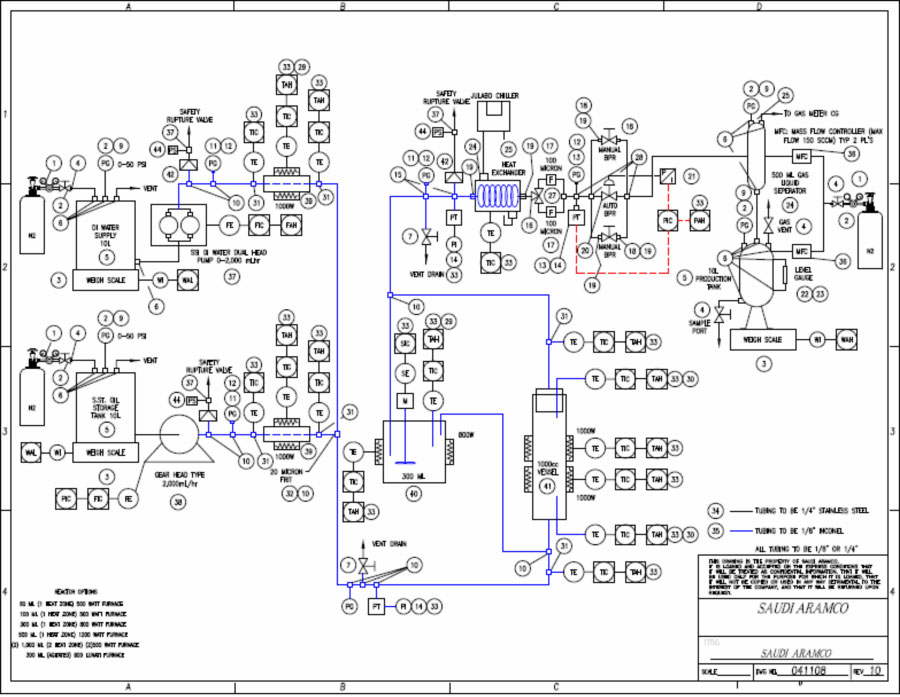

A petrochemical company was looking to develop a process that would break down “oil heavies” left at the end of their crude oil cracking processes so they could be converted into usable petroleum products. We helped them develop a process flow and supercritical water system that would result in the maximum amount of usable product.

A petrochemical company was looking to develop a process that would break down “oil heavies” left at the end of their crude oil cracking processes so they could be converted into usable petroleum products. We helped them develop a process flow and supercritical water system that would result in the maximum amount of usable product.