Download the

Download the ROI Sheet

Working in close collaboration with governments, private, and non-profit organizations, Supercritical Fluid Technologies designs and builds custom supercritical fluid extraction and reaction systems.

Our custom solutions incorporate and build upon many of the features found in our high end bench top systems, and facilitate the transition from laboratory-scale equipment to large scale pilot production and full scale processing systems.

A typical custom system is fully-automated, and includes a CO2 recycling system. The extremely low surface tension, low viscosity, high diffusivity, and tunable solvent strength of supercritical CO2 make it an ideal solution for a wide variety of industrial and scientific applications.

Case Studies

Pharmaceutical Pilot Scale System

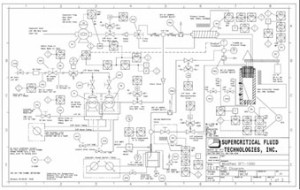

We designed and constructed a pilot scale extraction system for a major pharmaceutical firm to meet highly exacting specifications by coupling the precise pressure, temperature, and dosing control features of SFT’s high end bench top equipment with a rack mounted, 20-liter extraction vessel that was ASME code rated to 10,000 psi (690 bar). Included is a simple P&ID which demonstrates the components and functionality.

We designed and constructed a pilot scale extraction system for a major pharmaceutical firm to meet highly exacting specifications by coupling the precise pressure, temperature, and dosing control features of SFT’s high end bench top equipment with a rack mounted, 20-liter extraction vessel that was ASME code rated to 10,000 psi (690 bar). Included is a simple P&ID which demonstrates the components and functionality.

Microelectronics Manufacturing

In the microelectronics fabrication industry, SCF CO2 is increasingly being used as a non-toxic, environmentally-friendly alternative for device cleaning, drying, and lithographic processing. Replacing more toxic solvents with supercritical CO2 also eliminates pattern collapse, which often occurs when using traditional solvents on microelectronic devices with feature dimensions below 100nm.

Understanding the advantages of using supercritical CO2 for these applications, a client came to us looking to improve their process for resistive striping and surface deposition of photolithographic polymers. Custom components of the system we developed included:

- A special vessel configuration

- A unique lifting mechanism that provided 180 degree vessel rotation, creating easy access to the interior of the vessel for component installation

- A custom dense gas management package to deliver various resistive stripping solvents in a controlled manner,

- An integrated mass flow meter and weigh scale to complete mass balance calculations

Lithium Batteries Processing for Improved perfomance

A client came to us looking to use supercritical extraction technology to improve the strength, chargeability, and lifetime of lithium batteries. Through feasibility work completed in the SFT Inc. laboratories, we showed that using SCF CO2 to extract the impurities in polymeric lithium batteries does achieve the desired results. We then worked with the client to design and build a pilot scale SFE system specific to their process so they could refine the process for larger scale manufacturing.

Processing Medicinal Marijuana with the NPX-10 Extractor

The need for pharmaceutical grade cannabis oil has increased as researchers continue to investigate the application of cannabis oil for the treatment of various ailments such as muscle spasms, glaucoma, nausea, mood and behavioral disorders, sleep disorders, and chronic pain. With a myriad of cannabinoids present in the marijuana plant that can be used to treat a range of ailments and conditions, the investigation into producing a more effective extraction method and purer product has just begun. Supercritical Fluid Technologies has developed the SFT-NPX-10 Natural Products Extractor for researchers who want to investigate a higher quality of product using a more efficient and greener supercritical fluid carbon dioxide (scCO2) extraction process as the extraction solvent.

Not all essential oils are created equal, and the operating parameters that favor the extraction of particular bio-active compounds, flavanoids, or fragrances vary from plant to plant. For example, although humulus (beer hops) and cannabis are closely related members of the Cannabinaceae family, the conditions under which you can extract their essential oils are not. This being the case, an extractor configured to optimally extract hops is not necessarily have the same configuration as an extractor configured for extracting oil of cannabis. The SFT-NPX-10 SFE allows more ease in the separation of the bio-active cannabinoids and terpenoids from the cellulose, waxes, and colorants than is obtained when extracted with aggressive hydrocarbon-based solvents.

Optimized Supercritical Fluid Extraction of Capsaicinoids from the Capsicum Annuum Cultivar (Red Pepper)

The science and process for isolating commercially valuable substances from plant stock begins with cleaning, cutting, and drying and progresses to a level of crushing-milling-sieving. At this point the pretreatment is considered complete and the substance extraction process begins followed by resin purification. The capsicum annuum cultivar is processed in a similar manner where an extracted oleoresin is rich in valuable substances including capsaicinoids. Purified capsaicinoids have many commercial uses including inputs for analgesic ointments, nasal sprays, pain relieving dermal patches and creams, pepper spray, and mammalian pest control in farming. [1] Optimizing the thermodynamic processes for supercritical fluid extraction of capsaicinoids offers an opportunity to improve the manufacturing process cost efficiency for these valuable substances.

Supercritical Fluid Technologies worked with a client to develop the optimized processing parameters to extract Red Pepper in our laboratories and then also specified, designed and deployed the pilot processing unit for this application.

Supercritical Propane for the Extraction of Waxes

A client had approached Supercritical Fluid technologies Inc. with an interest in extracting a wax from their existing product to open new markets for their high value added materials. The optimal solvent for the client’s process was supercritical fluid propane. Supercritical Fluid Technologies specified, designed, and deployed a supercritical propane extraction system for this processing need that met all Class I division II safety standards for the use of propane in this process application.